Product Description

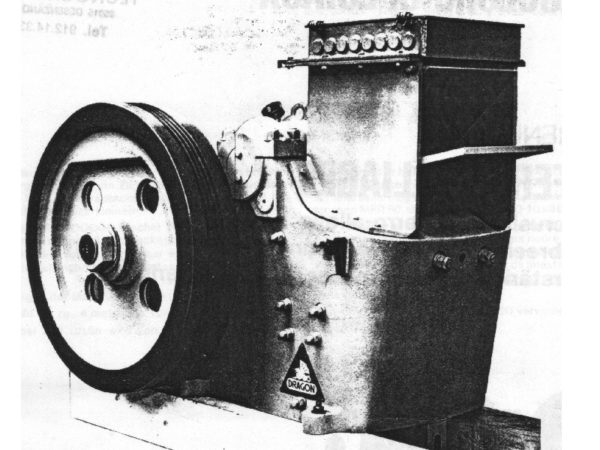

This crushers, specially designed for treating ferro alloys, is the only machines in the world capable of accepting lumps of super refined ferro-chrome measuring up to 140 x x 160 x 280 mm ( maximum weight 30÷40 Kg ) and of breaking them down to sizes between 0 to 2÷4 Kg ; with an output of 2 to 3 Tons pour hour. Considering the extraordinary toughness of ferrochrome, it will be clear that these crushers are capable of treating all other ferro alloys with even greater ease. The net weight of the crushers, which is built enterely of high tensile steel, is three times the weight of an jaw crusher with the same size of inlet in current production. The special bronze bearings with high features are amply lubricated by oil under pressure, and the push rod is water cooled. Moreover, special consideration has been paid to the design of the oil lubricating system so that pollution of the product by oil is excluded. The sectional drawing illustrates the very heavy construction and the robustness of these crushers.